Central Gas Station

The automatic medical oxygen manifold is using electromagnetic valve control with more accuracy and low failure rate. Reliable wall or horizontal installation. When the circuit malfunctions, exports remain and at this time and both sides gas supply at the same time. Both with digital and gauge pressure indication. Color display for easy reading. The pressure unit provides the bar, Mpa or psi for measure conversion. When change the medical gas cylinder the manifold have alarm function.

Manifold Type : 2 stage , 2 regulators Inlet Dia : 1/2” Outlet Dia : 22 mm Outlet pressure : 4-5 bar Automation : Full Automatic

Specifications LCD Display full Automatic Manifold Complying to HTM02-01, HTM2022 and C11 Full Automatic Manifold High-quality electromagnetic valve and gauge Pass the pressurization testing, welded in silver, much safety and stable With the function of over-pressure drain Applicable gas: O2, CO2, N2, and N2O, etc. With alarm system when pressure is abnormal Size of the connecting hose is customized

Manifold System

| Explanation | Gas Type | Model No |

| With alarm 40 m³/h | Oxygen | BR-OS-40 |

| With alarm 180 m³/h | Oxygen | BR-OS-180 |

| With alarm 40 m³/h | Nitrojen | BR-N2O-40 |

| With alarm 180 m³/h | Nitrojen | BR-N2O-180 |

Tail Pipe & Flexxible Hose

| Explanation | Gas Type | Size | Model No |

| Tail Pipe | Oxygen(Bull-Nose) | 5/8 (Male) | BR-TP-58 |

| Tail Pipe | Oxygen | 3/4” | BR-TP-34 |

| Tail Pipe | Nitrousoxide | 3/8” | BR-TP-38 |

| Flexxible Hose 60 cm | Oxygen(Bull-Nose) | 5/8 (Male) | BR-FH-58 |

| Flexxible Hose 60 cm | Oxygen | 3/4” | BR-FH-34 |

| Flexxible Hose 60 cm | Nitrousoxide | 3/8” | BR-FH-38 |

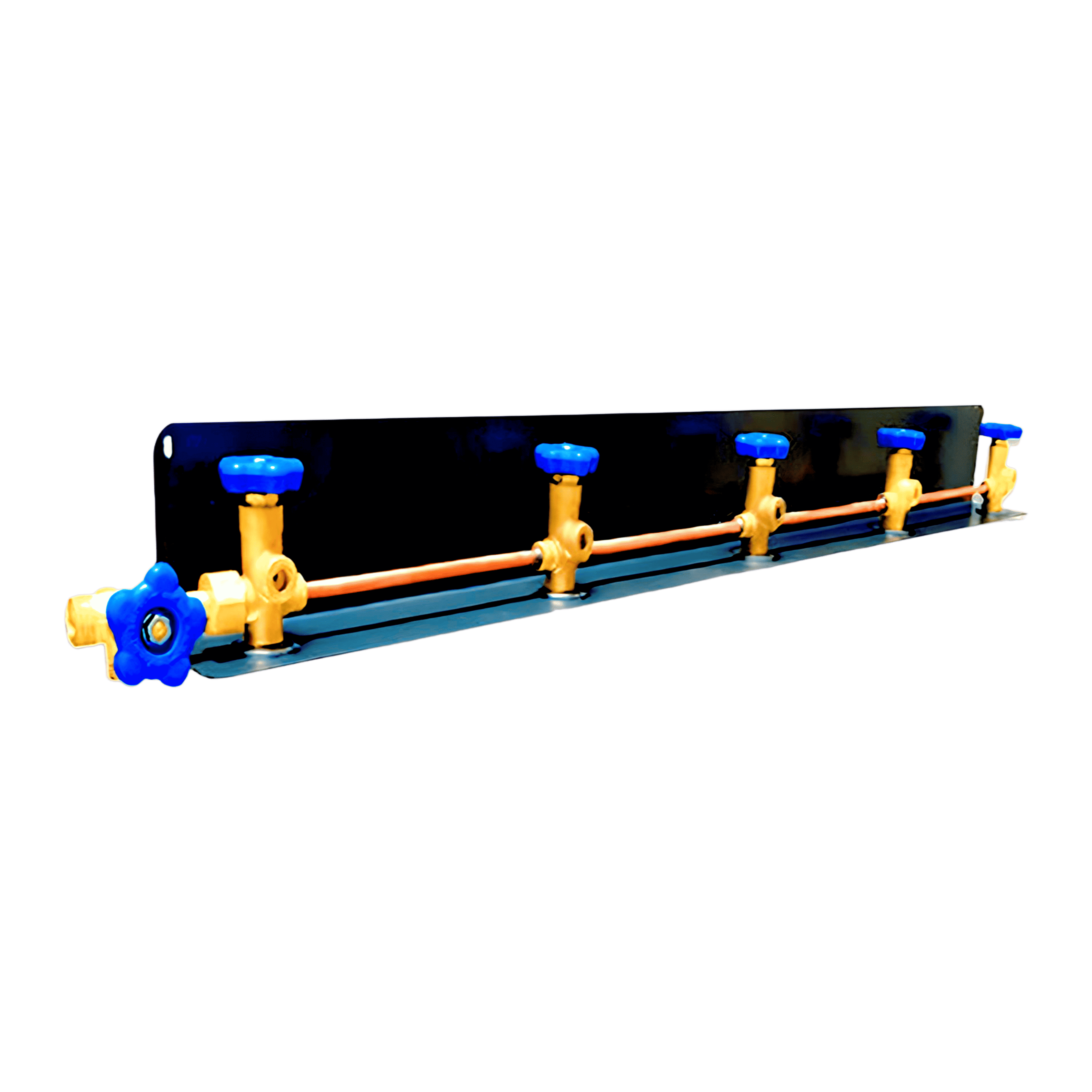

Cylinder Ramp

Manifold ramp is specially manufactured to pass oxygen from cylinders or cylinder bundles. Pipes used in collector distribution are manufactured from medical copper pipes suitable for wall thickness that will allow passage to high-capacity oxygen flow. This ensures a smooth flow even at the highest flow rate.

| Explanation | Lenght / mm | Model No |

| Single | 180 mm | BR-CO-1 |

| Double | 280 mm | BR-CO-2 |

| Triple | 330 mm | BR-CO-3 |

| Quadruble | 930 mm | BR-CO-4 |

| Quadruble | 1230 mm | BR-CO-5 |

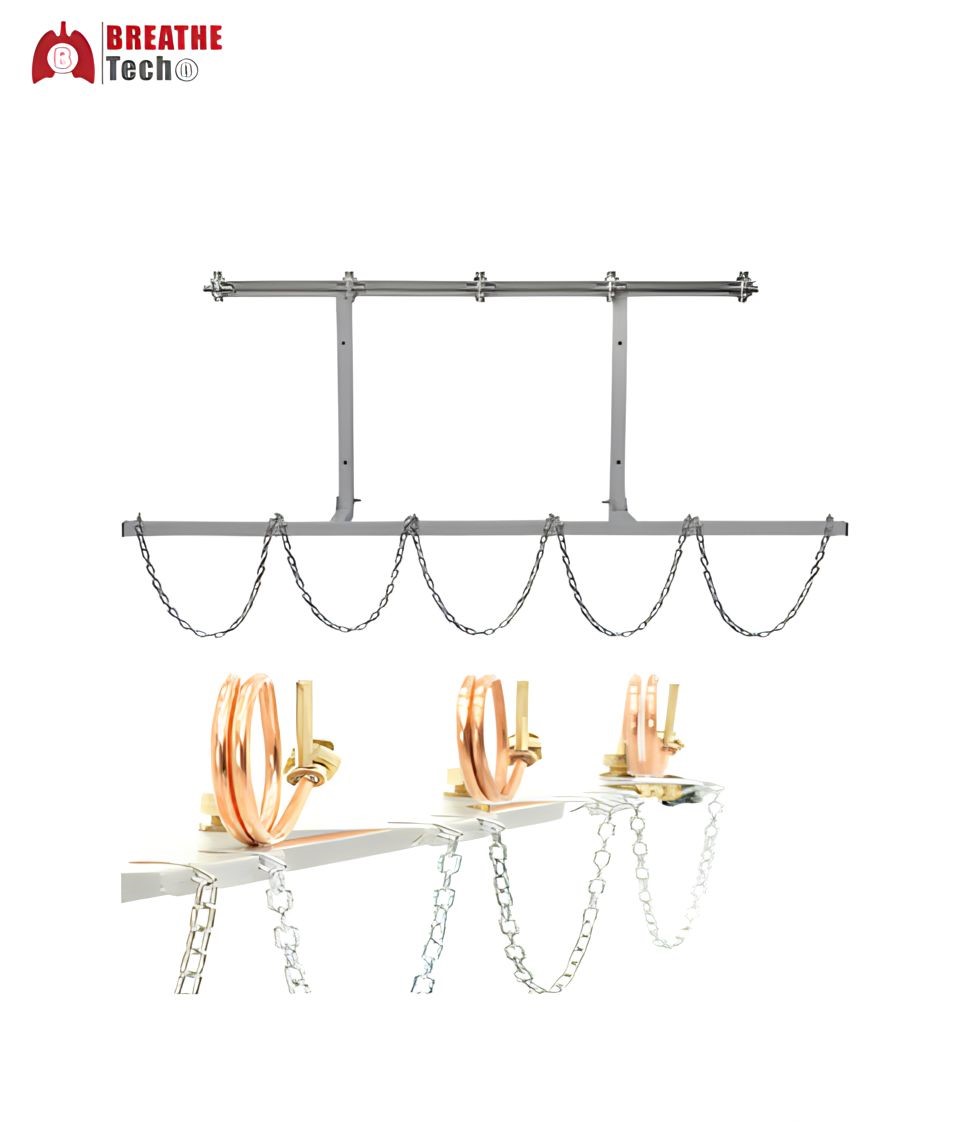

Cylinder Fixing Chain

It is the unit that can be mounted on the wall to fix the rollers. It prevents the rollers from swinging or falling, thanks to their separate sections and chains for each roller. Designed for 2, 3 and 5 cylinder connections.

| Explanation | Lenght / mm | Model No |

| Single | 180 mm | BR-CF-1 |

| Double | 330 mm | BR-CF-2 |

| Triple | 580 mm | BR-CF-3 |

| Quadruble | 930 mm | BR-CF-4 |

| Quadruble | 1230 mm | BR-CF-5 |

Medical Air System

Medical Air Plant is designed to provide a continuous supply of medical quality air. Medical air is mainly supplied via a medical gas pipeline system where the air is generated by compressors, dryers and filtration system. Medical Air plant with rotary screw compressors can be used in wide capacity range. Compressor capacities varies from 4 kW to 22 kW. High quality screw blocks with perfect lubrication systems enable continuous operation, stability and reliability.

| Model No | Compressor Capacity | Dryer Capacity | Tank Capacity | Bed Quantity |

| BR-4000 | 1*33 m³/h | 1*50 m³/h | 300 L | 10-30 |

| BR-4001 | 1*39 m³/h | 1*50 m³/h | 300 L | 20-50 |

| BR-4002 | 2*39 m³/h | 2*50 m³/h | 300 L | 20-50 |

| BR-4003 | 1*84 m³/h | 1*90 m³/h | 500 L | 50-100 |

| BR-4004 | 2*84 m³/h | 2*90 m³/h | 500 L | 50-100 |

| BR-4005 | 1*117 m³/h | 1*135 m³/h | 1000 L | 100-150 |

| BR-4006 | 2*117 m³/h | 2*135 m³/h | 1000 L | 100-150 |

| BR-4007 | 1*168 m³/h | 1*180 m³/h | 1500 L | 150-200 |

| BR-4008 | 1*168 m³/h | 1*180 m³/h | 1500 L | 150-200 |

| BR-4009 | 1*210 m³/h | 1*290 m³/h | 2*1000 L | 200-250 |

| BR-4010 | 2*210 m³/h | 2*290 m³/h | 2*1000 L | 200-250 |

Vacuum Central Station

Specifications

• Designed to be used for central vacuum systems in operating theatres ,ICU’s , laboratories and emergingies of hospials

• PLC controlled full automatic system

• Compact tank top design

• Medical type high efficiency bacteria filters

• Suitable low height medical gas plant rooms

• Available in Simplex, Duplex, Triplex,

• Different capacity receiver tank available

• Minimal maintenance, Maximum Durability

• Completely tested before shipment

| Model No | BR-VC-21 | BR-VC-40 | BR-VC-12 | BR-VC-13 | BR-VC-16 |

| System Capacity (m³/h ) | 21 | 40 | 100 | 100 | 160 |

| Power (kW) | 0,75x2 | 1,1x2 | 2,2x2 | 2,2x3 | 4x2 |

| Pump Quantity | 2 | 2 | 2 | 3 | 2 |

| Tank Capacity (L) | 500 | 500 | 1000 | 1000 | 1000 |

| Noise dB(A) | 62 | 64 | 66 | 69 | 71 |

Vacuum Tank

• Designed to use in central vacuum stations

• Different capacities for different stations

• Made of highly durable steel material

| Capacity[L] | Wall Thickness | Diameter | Lenght | Model No |

| 500 L | 5 mm | 600 mm | 2090 mm | BR-VT-60 |

| 750 L | 5 mm | 750 mm | 2130 mm | BR-VT-75 |

| 1000 L | 6 mm | 850 mm | 2200 mm | BR-VT-85 |

| 1500 L | 6 mm | 1000 mm | 2260 mm | BR-VT-10 |

Anaesthetic Gas Scavenging System

Anaesthetic gas scavenging system consisting of 2 side channel blowers, protection cover casing, electrical and control panel, remote start / stop /alarms panel, safety suction filter and depression control valve. Single and Double blower versios are avaliable blowers are oil-free, air cooled side channel regenerative type and suitable for continuous operation

| Model No | BR-GS-80 | BR-GS-130 | BR-GS-280 | BR-GS-230 |

| Capacity | 80 m³/h | 130 m³/h | 2x80 m³/h | 2x130 m³/h |

| Power | 0,4 kW | 0,75 kW | 2X0,4 kW | 2X0,75 kW |

| Power Qty | 1 | 1 | 2 | 2 |

| Noise Level | 60 dB | 60 dB | 66 dB | 66 dB |

AGSS Terminal Units

The AGSS connector is an essential device for operating theatres. During medical operations, the use of anaesthetic gases contributes to polluting the operating room. For the sake of a successful operation, it is important to remove these anaesthetic gases. The anaesthetic gas scavenging system (AGSS) creates a pressure drop and sucks up the pollutant gases.

Technical specifications:

• Can be used as under plaster,on plaster or pendant outlet

• Special port to enable safe connection

• Venturi Type outlet option

| Probe Type | BS | BS Probe | DIN(Venturi) | DIN Probe | Air Motor | Air Motor Probe |

| Model No |

Oxygen Production Systems

Oxygen Generators are new generation stations that allows on-site production of oxygen. This helps hospitals to supply oxygen from their own automated system independently. These systems are generally combined with cylinder systems for instant back up. Oxygen Generators deliver oxygen in a purity up to 95% at flow rate from 3 to 50 m3/h. Station delivers constant purity rate independent from the consumption. Ideal system consists of air compressors, dryers, O2 generator, active carbon tower, tanks and filters. The breathtech oxygen generators supply all of the advantages of a fully integrated oxygen generator. The continual measurement and monitoring of all operating values offers the highest possible protection for the whole compression process. The breathtech oxygen generators can be monitored and operated from any computer workstation anywhere in the world through the latest networking technology. The industry standard 4.0 is a real innovation for your security.

| Model No | O2 Generator Capacity | Compressor Capacity (m³/h) | Dryer Capacity (m³/h) | Carbon Tower Capacity (m³/h) | Air Tank Capacity | Oxygen Tank Capacity |

| BR-OG-3 | 3 m³/h | 42 | 60 | 42 | 300 L | 300 L |

| BR-OG-6 | 6 m³/h | 81 | 120 | 81 | 500 L | 500 L |

| BR-OG-9 | 9 m³/h | 122 | 182 | 122 | 750 L | 750 L |

| BR-OG-12 | 12 m³/h | 162 | 243 | 162 | 1000 L | 1000 L |

| BR-OG-15 | 15 m³/h | 203 | 303 | 203 | 1000 L | 1000 L |

| BR-OG-18 | 18 m³/h | 243 | 244 | 243 | 1000 L | 1000 L |

| BR-OG-21 | 21 m³/h | 284 | 425 | 284 | 1000 L | 1000 L |

| BR-OG-24 | 24 m³/h | 324 | 486 | 325 | 1000 L | 1000 L |

| BR-OG-30 | 30 m³/h | 405 | 607 | 408 | 2000 L | 2000 L |

| BR-OG-36 | 36 m³/h | 486 | 729 | 498 | 2000 L | 2000 L |

| BR-OG-42 | 42 m³/h | 567 | 850 | 576 | 2000 L | 2000 L |

| BR-OG-48 | 48 m³/h | 648 | 972 | 660 | 2500 L | 2500 L |

| BR-OG-54 | 54 m³/h | 729 | 1093 | 738 | 3000 L | 3000 L |

| BR-OG-60 | 60 m³/h | 750 | 1125 | 760 | 3000 L | 3000 L |